- [email protected]

- +86 312 590 7069 / +86 318 769 1559

+86 155 1129 3350

Introduction of Stainless Steel Dutch Woven Mesh

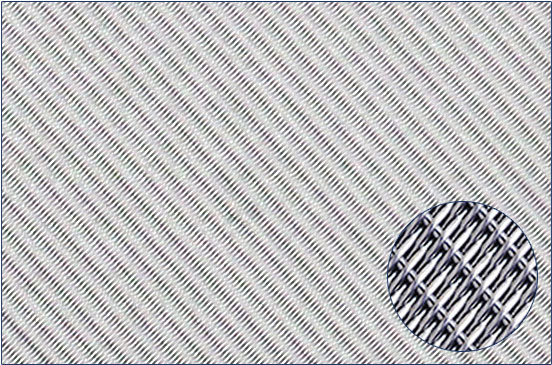

Stainless Steel Dutch Woven Mesh, also known as Dutch Weave Stainless Steel Mesh or Stainless Steel Hollander Weave Mesh. Stainless Steel Dutch Weave Wire Mesh is a kind of stainless steel filter mesh with high filter accuracy, it is also one kind of ss wire mesh widely used. The characteristic of stainless steel dutch woven mesh is that the wire diameter and mesh count in warp and weft directions are different. Generally, The weft wire is thinner with high mesh count, and the warp wire is thicker with low mesh count, the mesh hole shape shows rectangle. In contrast, for Reverse Dutch Weave Wire Mesh, the mesh count in the warp direction is greater than in the weft direction. The weft wire of dutch woven mesh is weaved tight, the max mesh count can be 2800 and with filtration accuracy with 3μm.

Compared with stainless steel square hole mesh, stainless steel dutch woven wire mesh is more thick and has better strength, higher filtration accuracy and longer service life. This is a very high filter accuracy which the square hole mesh can not achieve.

Stainless steel dutch woven mesh is widely used in precision pressure filter, fuel filter, vacuum filter, raw material for filter elements, aerospace, oil refining, medicine, sugar manufacturing, petroleum, chemical industry, chemical fiber, rubber, tire manufacturing, metallurgy, food, health research and other industries.

Stainless Steel Dutch Woven Mesh Features:

●Better structure strength and service time.

●Good mechanical properties.

●High filtration accuracy and stability.

●Good resistance of acid, alkali and corrison.

The Parameter and Specifications of Stainless Steel Dutch Woven Mesh

The main parameter of stainless steel dutch woven wire mesh are wire diameter, mesh count and filter accuracy. Because the wire diameter and mesh count of stainless steel wire cloth is not at same in warp and weft direction, so the wire diameter normally showed as warp diameter*weft diameter, and the mesh count shows as warp count and weft count.

The common used material of stainless steel dutch woven mesh are stainless steel wire: SS304, SS316, SS316L, Iron Wire, and Phosphor copper wire with Tin-plated. BZ Wire Mesh can also produce the dutch woven mesh in other material according to clients' requirements.

Stainless steel dutch woven wire mesh has Plain Dutch Weave, Twilled Dutch Weave two types. Plain Dutch Weave used for low mesh count product, and Twilled Dutch Weave for high mesh count products.

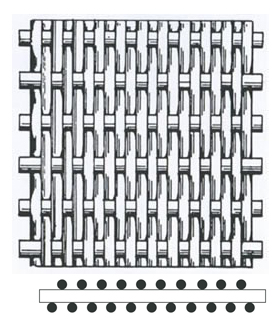

● Plain Dutch Woven Wire Mesh

Plain Dutch Weave is a combination of Dutch woven and Plain woven. Each thick thread diameter passes through the above and below of a latitude line alternately to form a fine hole for filtering, providing high tensile strength for the net. Flawed Dutch woven metal silk cloth is mainly used to filter and separate liquid and slurry products.

Advantage

● High mechanical stability.

● Crude steel wires obtain higher tensile strength.

● Fine openings to obtain better filtering efficiency and quality.

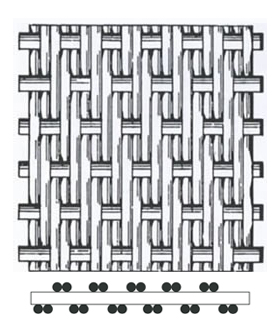

● Twilled Dutch Woven Wire Mesh

The Twilled Dutch woven mesh is a combination of Dutch woven and twilled weaving. The metal wire passes through two below and above, so as to allow heavier metal wires and higher mesons.

The stainless steel Twilled Dutch woven wire mesh is better than the twilled woven mesh, because its opening is thinner. It can withstand a larger load than the Dutch woven metal mesh. Used for filtering heavy objects.

Advantage

● High tensile strength.

● The structure is more stable.

● Filter performance is better.

● Can be used to filter ultra-fine products.

|

|

| Plain Dutch Weave | Twilled Dutch Weave |

| Dutch Woven Wire Mesh Specification (Plain Weave) | |||

| Gauge | Mesh Count | Wire Diameter(mm) | Filtration accuracy (μm) |

| 40 | 10x64 | 0.55x0.42 | 260 |

| 50 | 12x75 | 0.45x0.35 | 220 |

| 80 | 24x110 | 0.35x0.25 | 160 |

| 100 | 25x140 | 0.28x0.20 | 100 |

| 120 | 30x150 | 0.25x0.18 | 80 |

| 140 | 35x180 | 0.20x0.16 | 70 |

| 160 | 40x200 | 0.18x0.13 | 60 |

| 180 | 45x220 | 0.16x0.12 | 56 |

| 200 | 50x250 | 0.15x0.11 | 50 |

| 240 | 60x300 | 0.14x0.09 | 45 |

| 260 | 65x320 | 0.13x0.08 | 36 |

| 280 | 70x400 | 0.125x0.07 | 34 |

| 300 | 80x700 | 0.11x0.039 | 32 |

| Dutch Woven Wire Mesh Specification (Twilled Weave) | |||

| Gauge | Mesh Count | Wire Diameter(mm) | Filtration accuracy (μm) |

| 80II | 20x250 | 0.28x0.2 | 38 |

| 120II | 30x300 | 0.25x0.18 | 36 |

| 200II | 50x500 | 0.14x0.11 | 34 |

| 320I | 80x700 | 0.11x0.08 | 32 |

| 320II | 80x780 | 0.10x0.07 | 30 |

| 360 | 90x780 | 0.10x0.07 | 25 |

| 400I | 100x780 | 0.10x0.07 | 22 |

| 400II | 100x900 | 0.10x0.063 | 20 |

| 500 | 120x1100 | 0.07x0.05 | 17 |

| 630 | 150x1400 | 0.063x0.04 | 16 |

| 650 | 180x1800 | 0.07x0.04 | 14 |

| 685 | 165x1400 | 0.063x0.032 | 13 |

| 795I | 200x1400 | 0.07x0.04 | 12 |

| 795II | 200x1800 | 0.05x0.032 | 10 |

| 850 | 2l0x1900 | 0.045x0.03 | 10 |

| 1000 | 250x2000 | 0.045x0.028 | 8 |

| 1125 | 280x2200 | 0.036x0.026 | 7 |

| 1225 | 300x2200 | 0.036x0.026 | 6 |

| 1280 | 325x2300 | 0.035x0.025 | 5 |

| 1600 | 400x2800 | 0.03x0.018 | 3 |

● Reversed Dutch Weave Wire Mesh

The reversed dutch weave mesh is a special type of dutch weave woven wire mesh, the weft wire is thicker than warp wire. The common roll length of reversed dutch weave mesh is 10m, with from 40mm to 210mm, and the max width can be produced is 500mm, mesh count range from 40~350.

Advantage

● Smooth surface, high hardness, no breakage, no deformation.

● Resistant to high temperatures and corrosion, flexible transmission.

● Good filtration accuracy, high load strength.

|  |

| Reversed Plain Dutch Weave | Reversed Twilled Dutch Weave |

| Reversed Dutch Woven Wire Mesh Specification | |||

| Mesh/Inch | Wire Diameter/mm | Thickness(mm) | Width(cm) |

| 45x15 | 0.45x0.6 | 1.75 | 4-21 |

| 72x15 | 0.45x0.55 | 1.7 | 4-21 |

| 120x16 | 0.35x0.45 | 1.36 | 4-21 |

| 132x17 | 0.3x0.45 | 1.3 | 4-21 |

| 152x24 | 0.3x0.40 | 1.2 | 4-21 |

| 160x18 | 0.28x0.45 | 1.27 | 4-21 |

| 200x40 | 0.15x0.27 | 0.7 | 4-21 |

| 260x40 | 0.15 x0.27 | 0.65 | 4-21 |

| 300x40 | 0.15 x0.27 | 0.65 | 4-21 |

| 350x40 | 0.13 x0.27 | 0.6 | 4-21 |

Tags

INQUIRY FOR OUR PRODUCT