- [email protected]

- +86 312 590 7069 / +86 318 769 1559

+86 155 1129 3350

BZWIREMRSH offers various types of Woven Wire Mesh, Crimped Wire Mesh, Decorative Wire Mesh, and Architectural Wire Mesh. Among the most commonly used wire mesh weaving methods are as follows:

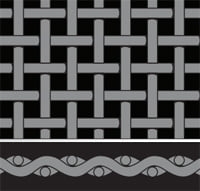

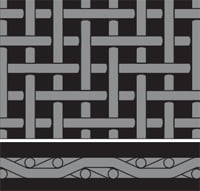

Each warp wire crosses over and under each weft wire, creating a 90-degree angle between the warp and weft wires. The warp and weft wires typically have the same diameter. Plain weave mesh is usually square, with uniform mesh sizes. It is used in most commercial applications and for high-flow filtration needs.

Each warp wire crosses over and under every two weft wires, and each weft wire crosses over and under every two warp wires. Twill weave allows for the use of larger wire diameters compared to plain weave with a similar mesh count.

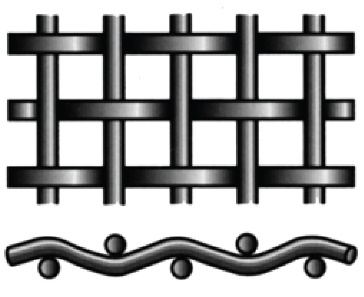

A common weaving method, the wire is pre-bent through a special mould before weaving the wire mesh. Generally used for weaving thicker wire mesh.

Crimped wire mesh is commonly used in industrial and mining enterprises, and also commonly used in architectural wire mesh.

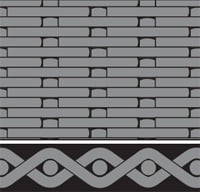

In Dutch weave, the warp and weft wires have different diameters, and the number of mesh openings in the longitudinal and transverse directions varies. During weaving, the metal wires are drawn closer, resulting in a denser mesh surface. The most common way to describe various Dutch weave specifications is by the number of mesh openings per inch and aperture size in microns.

It uses a plain weave method, but the warp wire diameter is larger than the weft wire diameter. The weft wires are closely woven together, forming a robust metal cloth while allowing good flow rates.

Similar to Dutch plain weave, but it is actually a double layer of weft wires woven in a twill pattern. This metal mesh is "non-transparent," has a very smooth surface, and is strong but limits flow rates. It is also known as micronic mesh and is typically used in high-pressure filtration.

It employs a plain weave method, but in contrast to Dutch plain weave, the weft wire diameter is larger than the warp wire diameter, resulting in different numbers of mesh openings in the horizontal and vertical directions. This metal wire mesh is very sturdy, easy to clean, and allows for high flow rates.

A diagonal weave of multiple metal wires composing the warp and weft wires. It forms a robust metal mesh with a relatively high number of openings per unit area and considerable flexibility. In some structures, it can exhibit capillary action.

If you want to know more information about Woven Wire Mesh, please click on the image below to get a free quote: