- [email protected]

- +86 312 590 7069 / +86 318 769 1559

+86 155 1129 3350

The architectural mesh is one of the main products series of BZWIREMESH, it is mostly used in the inner or outside decoration of buildings, so it is also called decorative mesh. And it contains several main types such as decorative woven wire mesh, cable-rod woven mesh, decorative expanded or perforated metal, etc.

As building decoration material, the architectural will need to be colored or need to be surface treated sometimes. The normally used surface treatment are spraying painting, powder coating, fluorocarbon coating and electroplating. They all have the advantages and disadvantages. It needs to be chosen according to the application scenarios.

Spraying painting is a simple way to color the mesh, it is normally used in the metal curtain products. The painting color is various, and the cost is quite low. But it is not suitable to paint stainless steel mesh because of the adhesion of painting is low. Also, the spraying painting is not suitable for outside applications, because it does have very good weatherability.

The powder coating is to paint and create a layer of PVC coating on the mesh surface, there are also various of color can be chosen. The cost of powder coating is relatively low, and it is suitable for carbon steel or aluminum material mesh. But the powder coating is very thick, so it is not be used to coloring the stainless steel mesh.

The fluorocarbon coating is a kind of high-end surface treatment, it is using PVDF painting and treated with thermal curing process. The fluorocarbon coating has very good adhesion and weather resistance, and it is suitable for stainless steel, aluminum or carbon steel material, it is able to be used in outside for long time.

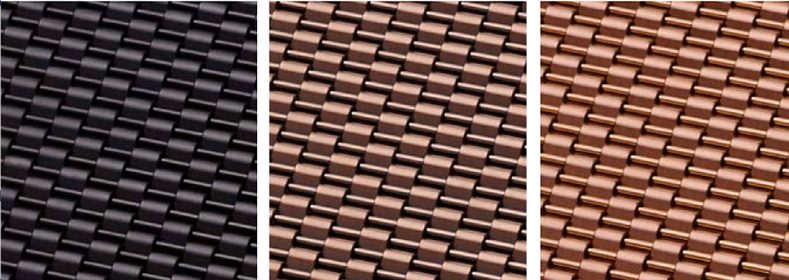

The electroplating is the first-class treatment for stainless steel mesh, it uses physical vapor deposition technique to create a layer in the surface of the mesh. The electroplated mesh has very shiny surface and the mesh will get very good smudge resistance, it is very suitable to be used in the decoration for high grade places. Of course, the cost of electroplating is also expensive.

Anyway there’s no the best, only the suitable. Clients need to choose the surface treatment according to the type, the material and the applications of the mesh.