- [email protected]

- +86 312 590 7069 / +86 318 769 1559

+86 155 1129 3350

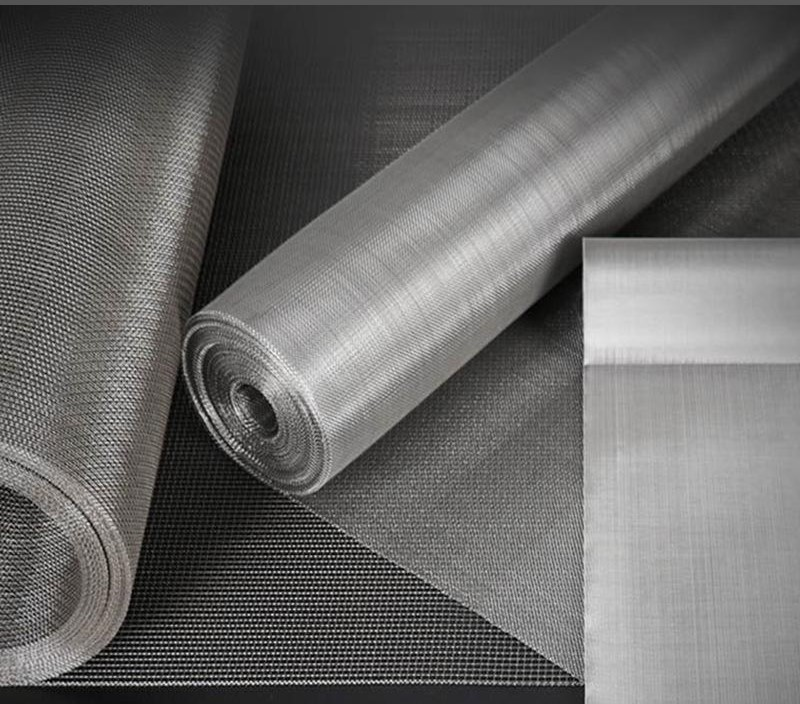

Duplex Stainless Steel Wire Mesh, is woven from duplex stainless steel wire,

commonly used materials are Duplex SAF 2205 and Duplex SAF 2507.

Compared with austenitic stainless steel, duplex stainless steel has enough resistance to stress corrosion, pitting corrosion and crevice tunnel corrosion. .In addition, the yield strength of duplex stainless steel can reach 400MPa ~ 550MPa, which is twice that of ordinary austenitic stainless steel.

The commonly used duplex stainless steel are Cr22 and Cr25 two types.

Cr22 is UNS S31803 (22cr-5ni-3mo-0.15n) with PREN value range 32-33. Its corrosion resistance is between AISI 316L and 6% Mo + N austenitic stainless steel.

Cr25 standard grade is UNS S32750 (25Cr-7Ni-3.7Mo-0.3N), PREN value is over 40, can be applied to harsh media conditions, has good corrosion resistance and mechanical properties, can be compared with super austenitic stainless steel.

It should be noted that the performance of duplex stainless steel also has some shortcomings, such as, the heat resistance of duplex stainless steel is low, and the working environment should be controlled below 300 ℃. In addition, the heat treatment of duplex stainless steel material is more difficult, and the production of duplex stainless steel wire is also much difficult. The smaller the wire diameter is, the greater the production difficulty is. When the wire diameter is less than 0.04mm, the wire will be very brittle. In addition, the surface of wire is more unsmooth, which greatly increases the difficulty of wire mesh production. The duplex stainless steel wire very easy to break in the woven process, so it need to pay more attention during production.

The production quantity of duplex stainless steel wire mesh is not much, and not that normally used. However, due to its special advantages, it plays an irreplaceable role in petrochemical equipment, nuclear industry equipment, seawater and wastewater treatment equipment, oil and gas pipelines, paper machinery and other industrial fields.