- [email protected]

- +86 312 590 7069 / +86 318 769 1559

+86 155 1129 3350

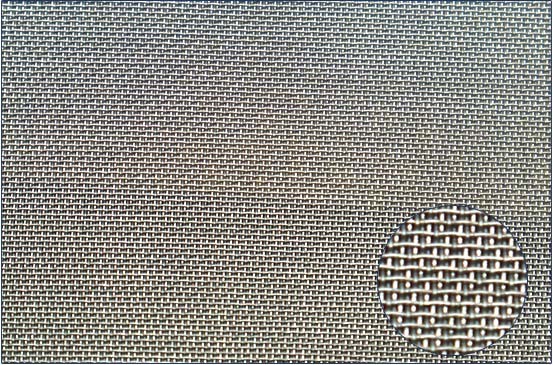

Introduction for Five-Heddle Woven Wire Mesh

Five-Heddle woven wire mesh is a special type of stainless steel wire mesh. Five heddle weave has rectangular opening. This mesh has a smooth surface on one side, which is widely used in filtration of petroleum chemical industries, in the form of filter ribbons, filter elements, and wire mesh gauze packing. BZWIREMESH is highly engaged in developing and supplying a wide range of Five-Heddle Wire Mesh.

The special weaving craft of Five-Heddle Wire Mesh makes it possible to produce the mesh with high flow rates combined with strong mechanical stability. The smooth surface which is easy to remove the filter muck and clean the filter media. Five-Heddle wire mesh have proven especially applicable in drum filter equipment and in disc filters where the build up of the filter cake, the removal and the cleaning are performed in continuous cycles.

Five-Heddle Woven Wire Mesh offers high flow rates and it is suitable for high mechanical loads, featuring a lightly structured mesh surface. It is widely used in drainage filtration, undercurrent filtration and be also suitable for dehydration in paper-making and chemical fillers.

Materials of Five-Heddle Woven Wire Mesh:High quality stainless steel wire of 304,304L,316,316L.Obtainable with us in different size and shape as per the demand of our customers.

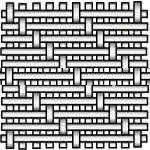

Five-heddle weave wire mesh has two normally used weaving method.

1.Each warp wire alternately goes under and above each one and four weft wires, and each weft wire goes under and above each one and four warp wires alternately.

2. Each warp wire alternately goes under and above each two and three weft wires, and each weft wire goes under and above each two and three warp wires alternately.

Five-heddle Weave

Common Specification of Five-Heddle Woven Wire Mesh

| Common Specifications of Five-Heddle Weave Wire Mesh | |||||||

| Mesh Count | Wire Diameter | Micro retention | Weight | Thickness | |||

| Warp | Weft | Warp mm | Weft mm | abs. μm | nom. μm | kg/m2 | mm |

| 132 | 85 | 0.14 | 0.2 | 0.09-0.11 | 0.052 | 1.47 | 0.44 |

| 107 | 132 | 0.16 | 0.14 | 0.055-0.065 | 0.055 | 1.3 | 0.44 |

| 107 | 125 | 0.16 | 0.14 | 0.065-0.08 | 0.07 | 1.27 | 0.45 |

| 107 | 59 | 0.16 | 0.16 | 0.16-0.18 | 0.077 | 1.09 | 0.45 |

| 80 | 60 | 0.2 | 0.2 | 0.20-0.22 | 0.127 | 1.4 | 0.55 |

| 77 | 40 | 0.24 | 0.24 | 0.38-0.40 | 0.095 | 1.65 | 0.68 |

| 65 | 36 | 0.3 | 0.3 | 0.26-0.29 | 0.1 | 2.27 | 0.84 |

| 55 | 36 | 0.3 | 0.3 | 0.25-0.28 | 0.175 | 2.05 | 0.84 |

| 48 | 45 | 0.4 | 0.4 | 0.17-0.21 | 0.13 | 3.79 | 1.11 |

| 48 | 45 | 0.29 | 0.29 | 0.24-0.26 | 0.23 | 2 | 0.83 |

| 48 | 25 | 0.3 | 0.3 | 0.46-0.50 | 0.25 | 1.64 | 0.82 |

| 30 | 18 | 0.5 | 0.5 | 0.60-0.65 | 0.37 | 3 | 1.48 |

| 28 | 17 | 0.47 | 0.47 | 0.75-0.80 | 0.46 | 2.53 | 1.41 |

| 24 | 20 | 0.6 | 0.6 | 0.65-0.75 | 0.49 | 3.96 | 1.7 |

| 15 | 13 | 0.9 | 0.9 | 1.15-1.20 | 0.85 | 5.67 | 2.6 |

Tags

INQUIRY FOR OUR PRODUCT